Search This Blog

Use this blog to post about or look for information on our monthly meetings, jobs, equipment, openings, shows, sales, workshops, classes, residencies, and everything else relating to being a clay artist.

Posts

Showing posts from December, 2008

Posted by

John Britt

Last Post for 2008!

- Get link

- Other Apps

Posted by

John Britt

Perfect Drip

- Get link

- Other Apps

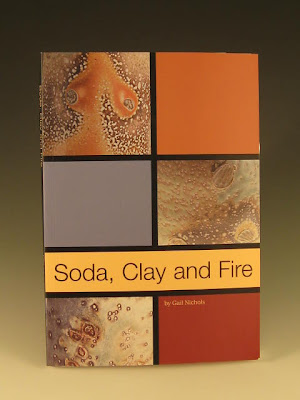

Posted by

John Britt

"Soda, Clay and Fire" Gail Nichols

- Get link

- Other Apps

Posted by

June Perry

SODA SALT TEST TILES ON MY BLOG

- Get link

- Other Apps

Posted by

John Britt

Detail of Soda Stack

- Get link

- Other Apps

Posted by

John Britt

Soda Firing Stack

- Get link

- Other Apps

Posted by

John Britt

Experimental Soda Firing

- Get link

- Other Apps

Posted by

John Britt

Judy Shreve Ewers

- Get link

- Other Apps

Posted by

Kari Weaver

Web Page research overload!!

- Get link

- Other Apps

Posted by

John Britt

"Re-Construction"

- Get link

- Other Apps

Posted by

John Britt

Cutest Dog Ever!

- Get link

- Other Apps

Posted by

John Britt

Best Cookies Ever!

- Get link

- Other Apps

Posted by

Sarah-potterknitter

No words needed

- Get link

- Other Apps

Posted by

John Britt

Penland Potters

- Get link

- Other Apps

Posted by

John Britt

Sarah Danforth's Caged Bird

- Get link

- Other Apps

Posted by

John Britt

Glaze Class - January 12 - 16, 2009

- Get link

- Other Apps

Posted by

June Perry

Soda Test Tiles

- Get link

- Other Apps

Posted by

Susan Feagin

Party has the floor!

- Get link

- Other Apps

Posted by

June Perry

Soda Test Tiles

- Get link

- Other Apps

Posted by

John Britt

Soda Firing

- Get link

- Other Apps

Posted by

Kyle Carpenter

Sticker Contest, anyone?

- Get link

- Other Apps

Posted by

sculptedelementdesign

Not going to be able to host at Mushroom Factory in Jan.

- Get link

- Other Apps

Posted by

John Britt

Tribute Cake

- Get link

- Other Apps

Posted by

Kari Weaver

Who won the Chocolate vote?

- Get link

- Other Apps

Posted by

June Perry

2009 Studio/work To do list

- Get link

- Other Apps

Posted by

Kyle Carpenter

BRAIN STORM personal goals for 2009

- Get link

- Other Apps

Posted by

Sarah-potterknitter

Clay Order??

- Get link

- Other Apps

Posted by

John Britt

December Clay Club! (rev.)

- Get link

- Other Apps

Posted by

John Britt

The Tour is over!

- Get link

- Other Apps

Posted by

Kyle Carpenter

Fire on the Mountain

- Get link

- Other Apps

Posted by

Kari Weaver

Expiration Date?

- Get link

- Other Apps

Posted by

John Britt

Thickness Matters

- Get link

- Other Apps

Posted by

John Britt

Transporting Pots

- Get link

- Other Apps

Posted by

John Britt

Processing Limestone

- Get link

- Other Apps

Posted by

John Britt

December Clay Club!

- Get link

- Other Apps